Test with ozone

Size your project

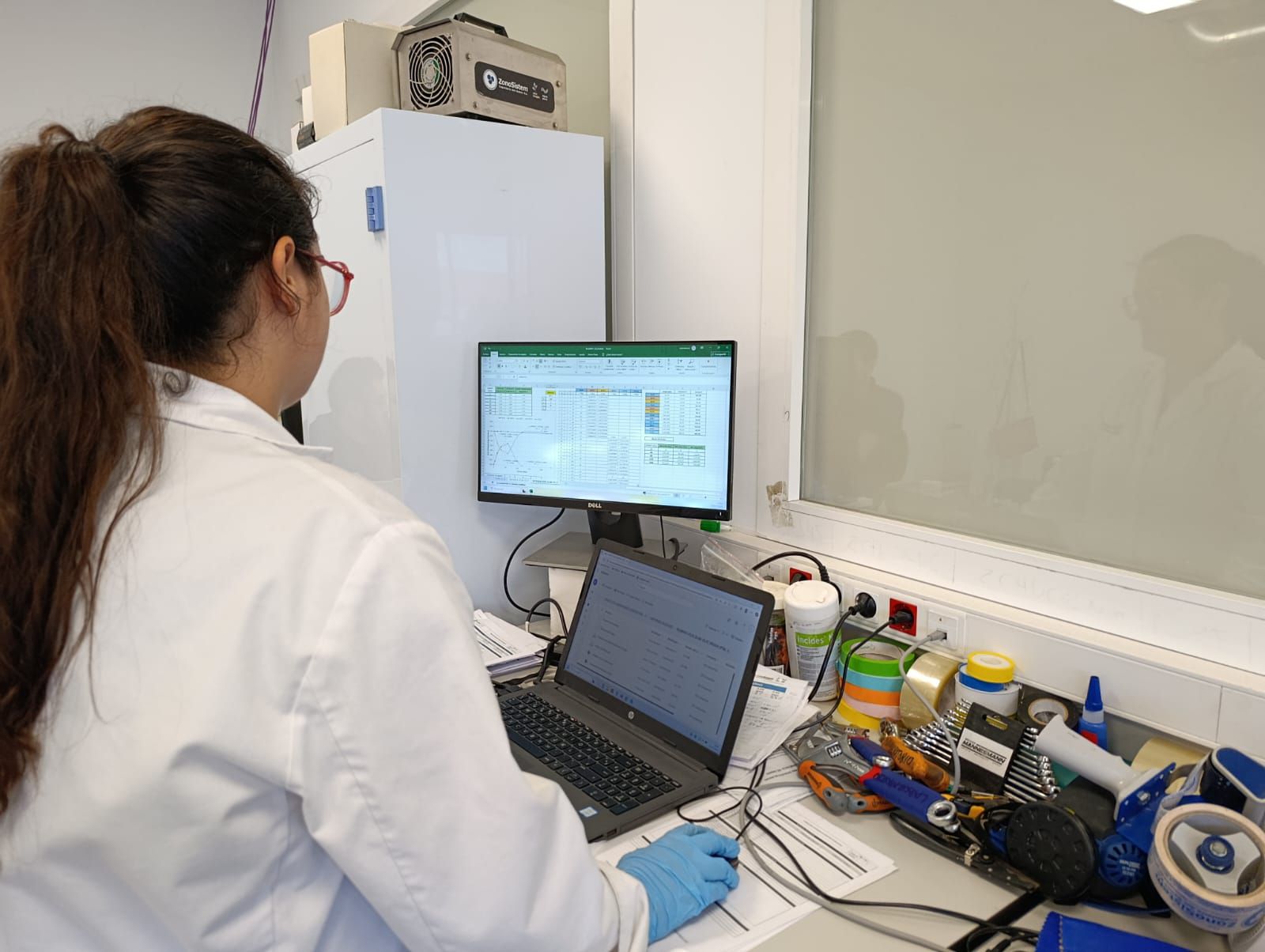

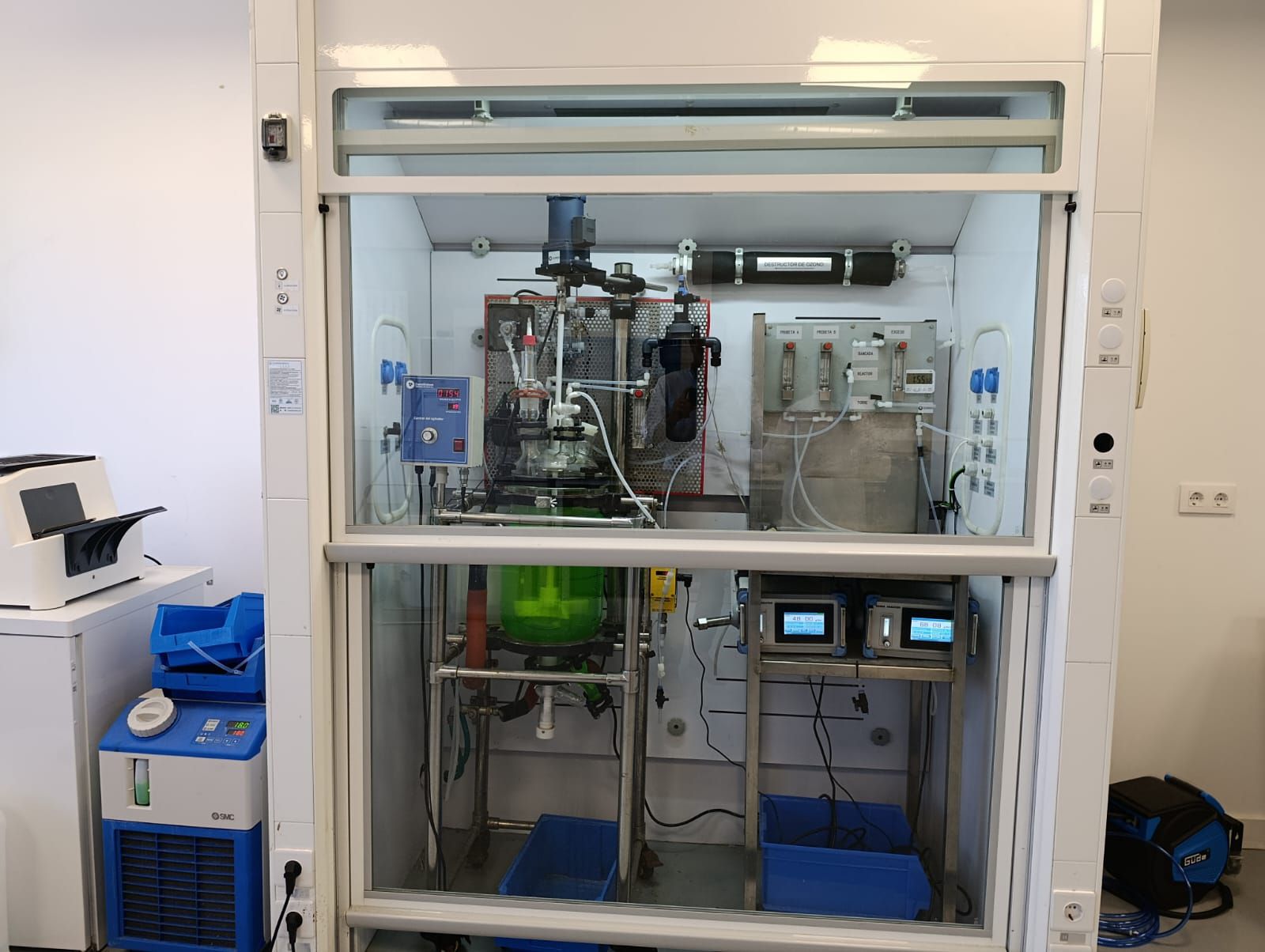

Laboratory area

A laboratory pilot with ozone serves to evaluate the effectiveness and feasibility of an ozonation process under controlled conditions. These types of tests are performed in a laboratory environment, using small-scale ozone equipment.Pilots for water treatment with ozone are an essential tool to guarantee the quality of the treated water. These pilots allow the effectiveness of the treatment to be evaluated under controlled conditions, which is essential for the success of a water treatment project.

Avoid the use of chemicals and reduce your handling costs

Ozone is generated on-site; there is no need to store or transport chemicals.

Prevent discharges, unnecessary risks, and protect the environment

The system is automated and does not require labor for its application

Problems disinfecting and purifying the water in your industry?

Advantages of conducting studies prior to implementing an ozone system

.jpg)

Efficiency of the ozonation process under controlled conditions

Definition of piloting objectives. The objectives of the piloting must be defined, such as the effectiveness of the process, the economic viability or the safety of the process. Complete pilot report is delivered

Identify the optimal operating parameters of the process

ZonoSistem also applies ISO quality standards in its ozone water piloting laboratory. Ozone equipment must be selected that is suitable for the pilot's conditions.

They allow data to be collected to carry out economic feasibility studies

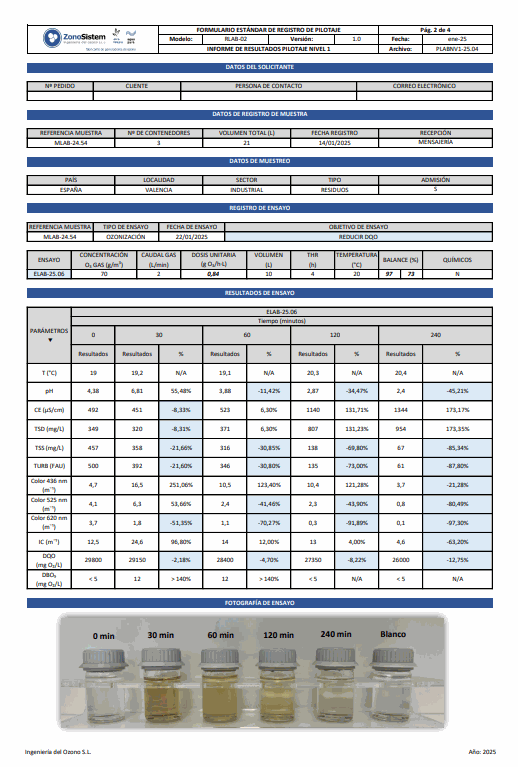

Analysis of the results: The results of the pilot must be analyzed to evaluate the effectiveness of the process. The report issuance period is 7-15 calendar days from receipt of the sample.

What types of piloting exist?

Test Level 0: Susceptibility

Level 0 piloting is the most basic. It is used to check the effectiveness of the treatment in a single parameter. This type of piloting is useful to evaluate the viability of a treatment in a specific case.

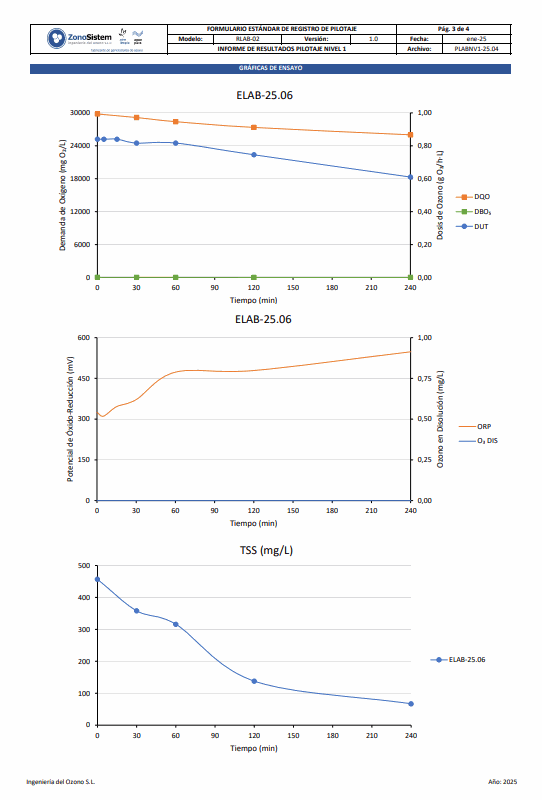

Test Level 1: Treatability

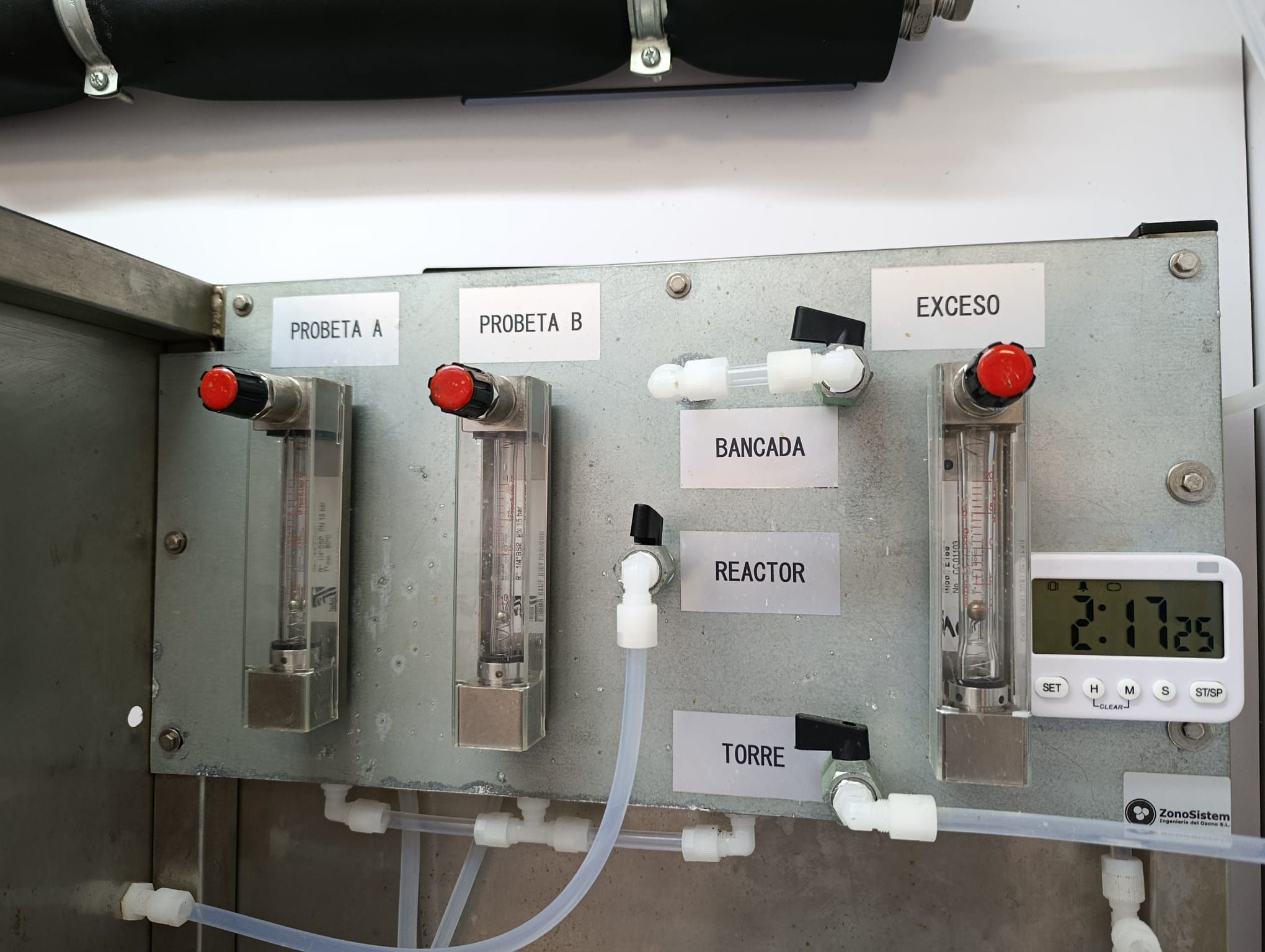

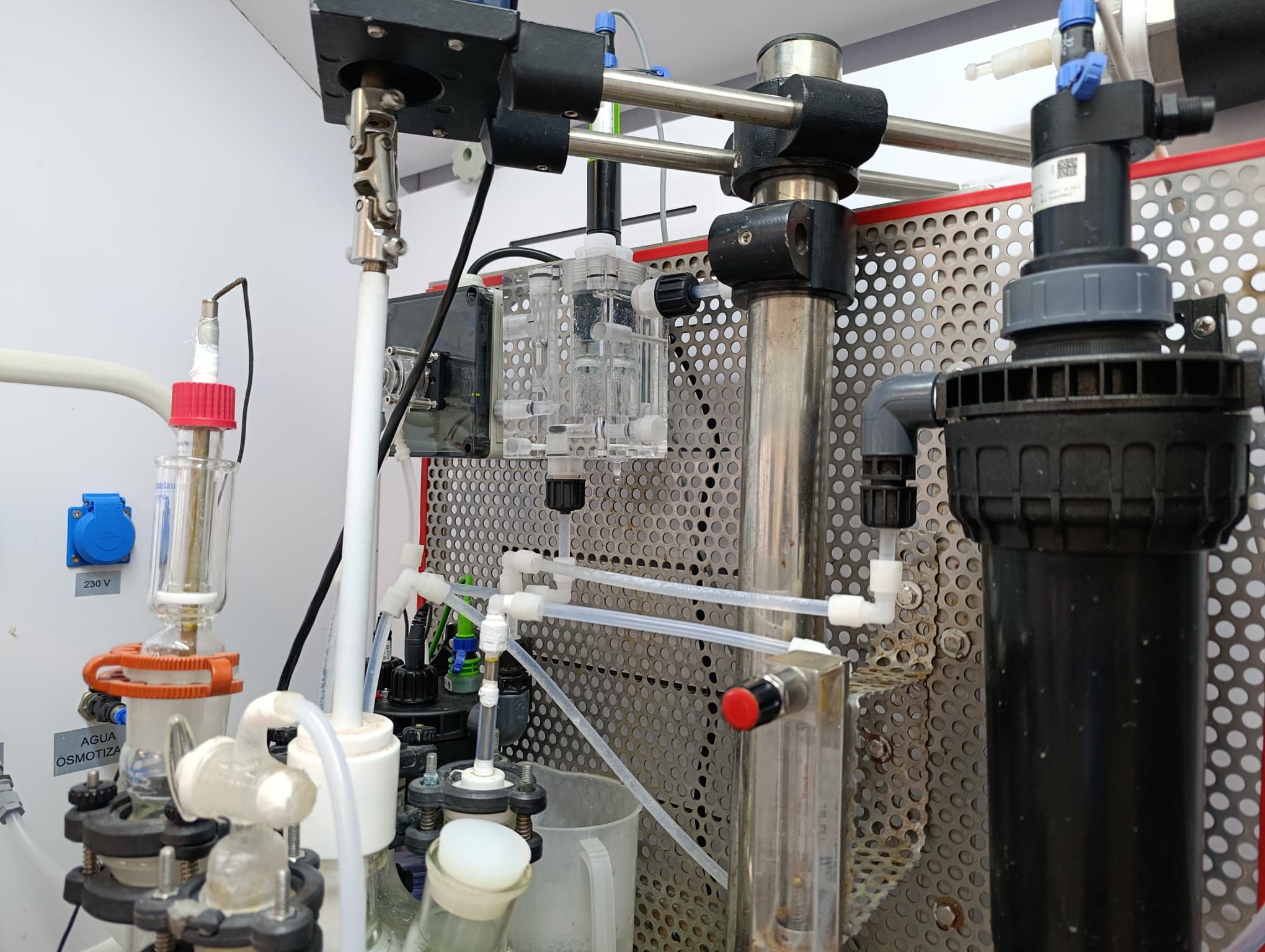

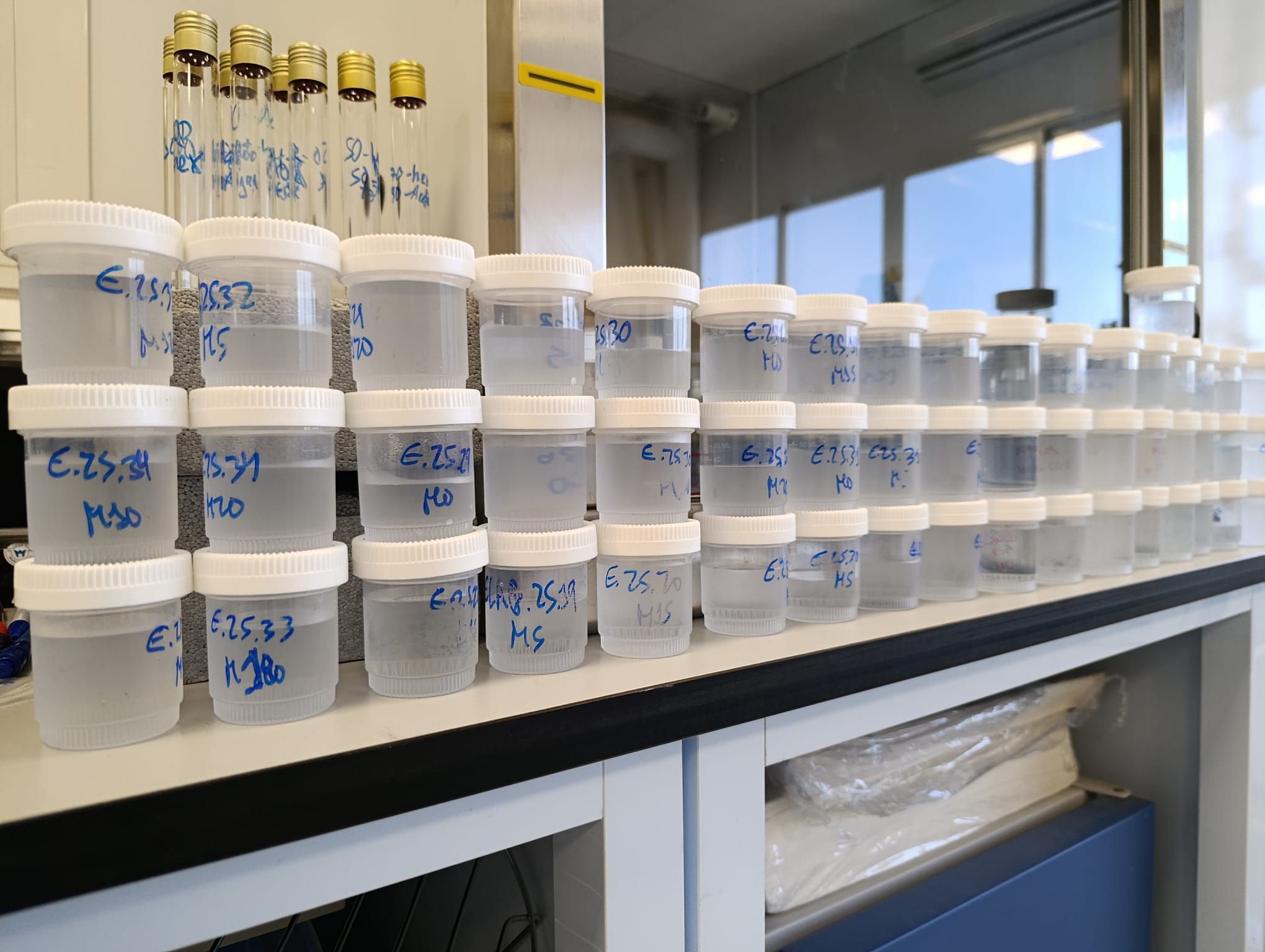

Level 1 Pilot Test is more complete than Level 0. A series of standard parameters are analyzed, and samples are taken at different time intervals. This type of pilot test allows evaluating the treatment's effectiveness under more realistic conditions and estimating ozone demand. The test is conducted in a 10-liter reactor.

Level 2 Pilot Test: Precision

Level 2 pilot testing is characterized by the large volume of test water, using a 1,000-liter reactor. It also employs a more efficient ozone injection and dissolution technique, such as pressurized recirculation. The ozone generator used reaches concentrations of up to 150 g/O₃/m³.

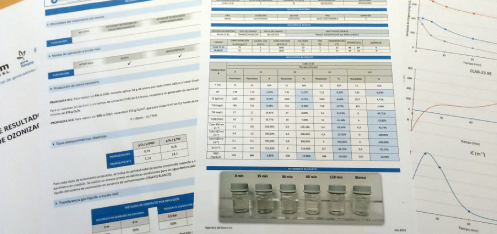

Example of Level 1 Pilot Test Results Report

Proceso de Pilotaje

En ZonoSistem ofrecemos nuestro pilotaje de Nivel 1 como un servicio de vanguardia diseñado para ofrecer una comprensión exhaustiva de la eficacia del ozono en la mejora de la calidad del agua. El proceso comienza por la recepción de una muestra representativa del cliente con un volumen de 10 litros. Un reactor de 10 litros se prepara cuidadosamente para recrear las condiciones óptimas de ozonización mediante burbujeo y agitación a presión atmosférica. Se realiza un seguimiento continuo de parámetros físicoquímicos y se estudian las relaciones entre ozono disuelto, potencial oxido reducción, demanda unitaria de transferencia y consumo total de ozono. Se extraen muestras a diferentes intervalos de tiempo ( pH, conductividad, temperatura, TSD, TSS, turbidez, color, DQO, etc...). Además, dependiendo del tipo de pilotaje se podrán realizar ensayos en tensioactivos, fenoles, toxicidad, microbiología etc...

Finalmente, se genera un informe con todos los resultados con el objetivo de tomar decisiones para el proyecto final.

Pilot Test Examples

Pilot test for Color and COD reduction

Activated Carbon pilot test

Water Microbiology pilot test

Coliform pilot test

Pilot test for Color and Sulfite reduction

.jpg)