GHBBZO6-E Professional Ozone Generator

Ozone generator to treat water flows up to 12 m3/h at pressures from 0.1 to 5 bar. Includes compressor, oxygen concentrator, pump, venturi, Redox and electronic control with touch screen. 6 gO3/h, at 35 g/Nm3, 230V, 50Hz, 1400W.

[Design] Ozone Generator, designed to maintain a constant amount of dissolved ozone in a water pipe.

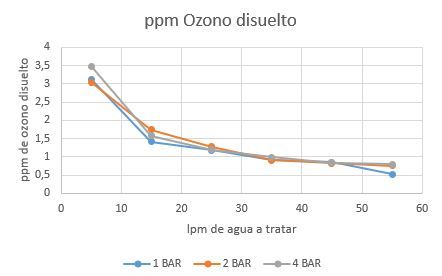

[High performance] It achieves high doses of dissolved ozone, thanks to its accelerator pump, venturi and stainless steel reactor.

[Automatic start control] It starts automatically thanks to its analog flow sensor.

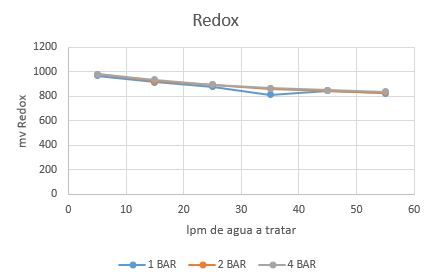

[Automatic power control] Allows you to select the level of redox you want and the equipment adjusts automatically.

[No replenishment of chemicals] Ozone is generated on-site. The equipment includes an oxygen concentrator.

[Simple Installation] You only have to attach the equipment to the pipe, and connect it to a light point.

[Maximum quality] Ozone generator made with top quality materials, resistant and durable.

Manufacturing in 10-15 days

Ozone generator

To inject ozone in a pressurized water pipe (in a homogeneous and automatic way).

What do you use it for?

This ozone generator is ideal for providing highly ozonated water continuously and homogeneously. Ozonized water is a powerful disinfectant, which is generated on site. Ozone leaves no residue. It is widely used in private and public swimming pools; fruit, vegetable and other industrial laundries; for washing and rinsing; small agricultural and garden irrigation, etc.

Product Details

| Ozone Generation system | A Module of 6 gO3/h with borosilicate dielectric. air cooled |

| Compressed air unit | Pre-filter + Compressor |

| Oxygen concentrator | Two-column activated alumina concentrator, 95% purity |

| Control | Electronic control with touch screen; Gas/Hydro Mode selector; and automatic start when detecting water flow |

| Sensors | Amps in Ozone, Compressed Air Pressure, Oxygen Pressure, Water Flow. |

| Technical Valves | Outlet ozone solenoid valve, Oxygen flowmeter with manual regulation |

| Included in the packaging | Electrical Connection Cable + Fixing Earmuffs + User Manual |

| Ozone Production | 6 GO3/H |

| Ozone concentration |

Maximum = 55g/Nm3 Optimum = 35g/Nm3 |

| Air/Oxygen flow | 3 lpm |

| Power supply | 230 V, 50Hz |

| Electric Power | 1400 W |

| Gas connection | OUT Tube 8 mm outter diameter |

| Hydraulic connexion | 2" female thread |

| Dimensions | 600 x 250 x 1000 mm (Width x Depth x Height) |

| Packed size | 800 x 1200 x 500 mm (Width x Depth x Height) |

| Weight | 85 Kg |

| Room fittings | The room must be well ventilated. It is recommended to install an ozone leak sensor and a sign with safety warnings in the room. |

| Humidity | <85% |

| Room temperature | 5 - 35ºC |

| Fluid temperature | 5 - 35ºC |

| Hydraulic Working Pressure | 0 - 5 bar |

| Quality of the water to be treated | Osmosis, distilled, drinking and agricultural water. |

| Working pressure | 0 - 0,4 bar |

| Made by | ZonoSistem |

| Made in | Spain |

| Sold from | 2022 |

| Last revision | 2022 |

| Certificates | CE, BIOCIDA PT2, PT4, PT5, PT11 |

| Warranty | 2 years extendable indefinitely, with maintenance contract |

| UFI number | G000-W09P-Y00M-TV8V |

Functioning

When it is working in Hydro Mode: the air compressor will start when the equipment detects any water flow, and will air from the atmosphere. The air will enter the PSA where nitrogen is removed and oxygen is concentrated to a purity of 95%. The resultant flow of oxygen will be conducted to the generation system, where the corona discharge is applied and the oxygen is transformed into ozone. Note that with the oxygen flow meter you can regulate the desired flow. Then accelerator pump will start and the ozone will be conducted to the venturi where it will be sucked in and mixed with the water. After that, the water with ozone will enter the homogenization and contact tank. Is in the tank where the Redox level of the water is measured. That will provide a constant water flow with a controlled, continuous and homogeneous amount of ozone. This will happen without generating any loss of pressure in the customer's pipe.

When the equipment is working in GAS Mode the ozone will be directed towards the ozone gas outlet, leaving the HYDRO part deactivated. With this gas mode you can carry out treatments in environments without people or you can also bubble ozone in a tank.

Performance curves

Documentation included

Safety manual.

User manual, installation and start-up.

Maintenance manual.

Declaration of conformity.

Certificate of guarantee.

Compliance with the biocidal regulation.

Results of the Quality Test in the factory.

Technology

This GHBBZO ozone generator uses high frequency corona discharge technology with borosilicate dielectric.