Ozone in Wastewater Pumping Stations (WWPS)

Ozone solution for odor problems

Use of Ozone in WWPS

Efficiency and sustainability in wastewater management: ozone treatment in WWPS

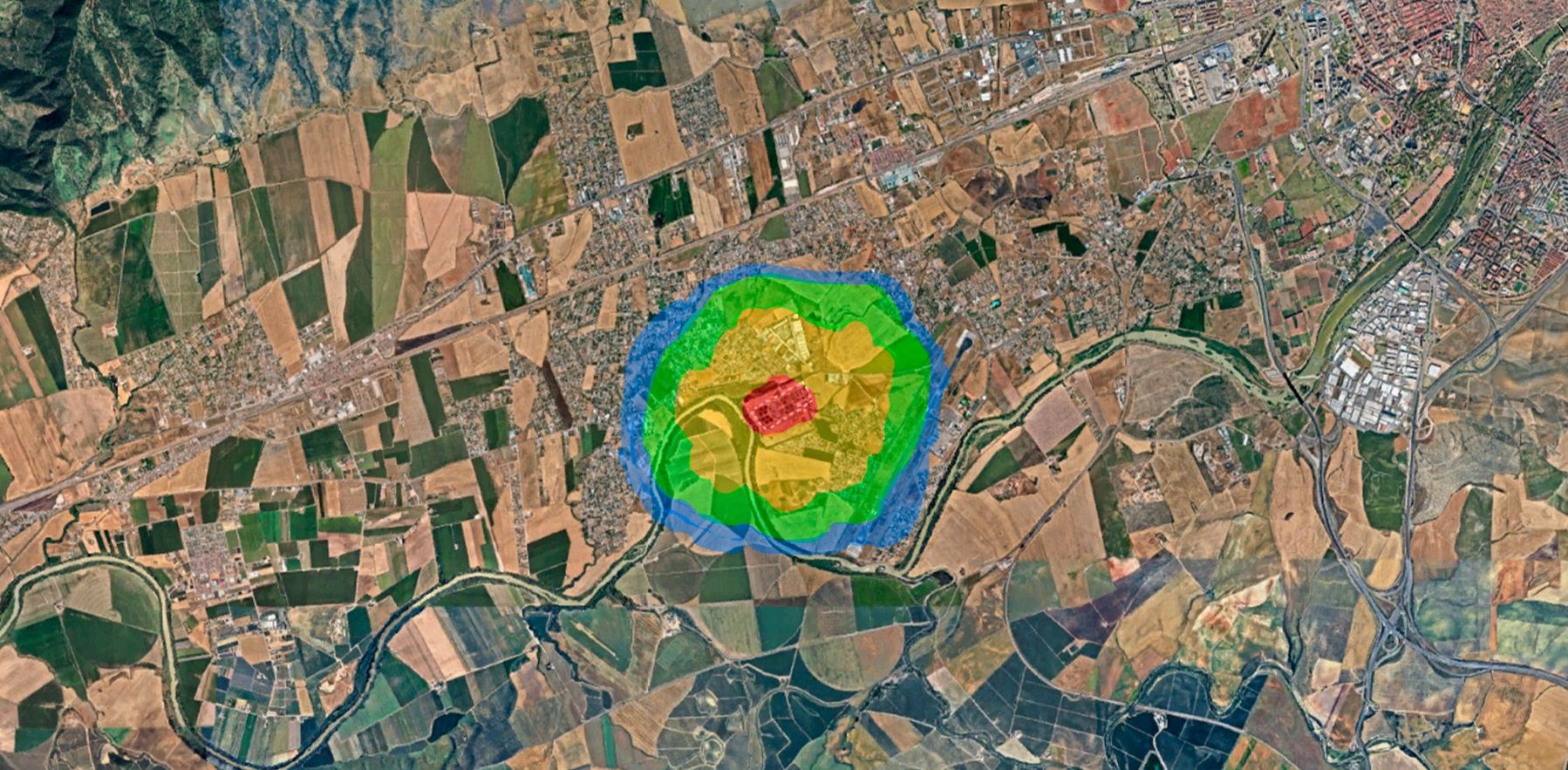

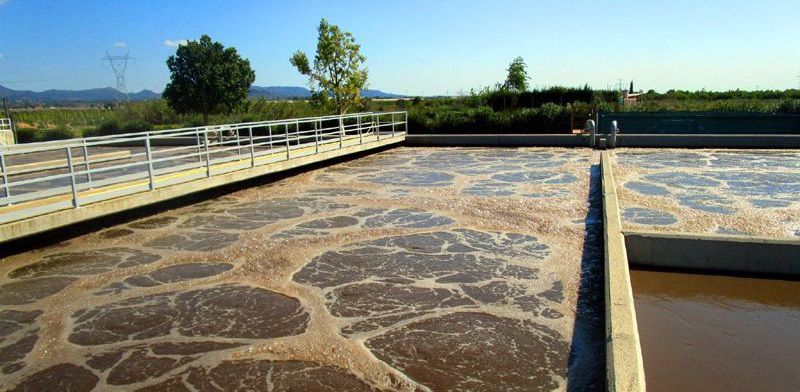

Wastewater Pumping Stations (WWPS) play a key role in the water cycle management, and the incorporation of clean technologies such as ozone treatment sets a new standard in sustainability. Ozone, a powerful oxidizing agent, effectively reduces odors, organic matter, and emerging contaminants before the water reaches its final destination (WWTP or outfall). This advanced solution improves environmental quality, eliminates odor problems caused by hydrogen sulfide (H2S), reduces the impact on sewage networks, and reinforces the commitment to more efficient and responsible water management.Ozone is a powerful oxidant applied to water for purification

Ozone is generated on-site, eliminating the need for chemical storage and transportation

Ozone contributes to sustainability and reduces the carbon footprint

The system is automated and does not require manual labor for application

Issues with your WWPS?

Problems with direct discharge to outfall?

Odor issues in residential and recreational areas?

Hydrogen sulfide levels above regulations?

Want to improve the quality of the water sent to the WWTP?

Anaerobic bacteria proliferation in the pumping well?

High costs in the gas treatment systems of the pumping station?

Advantages of applying ozone in a WWPS

Radical elimination of odors

Ozone effectively eliminates compounds responsible for bad odors such as hydrogen sulfide and volatile organic compounds. Its oxidizing action works instantly, improving the WWPS environment without generating waste or using additional chemicals.

Reduction of grease and sludge accumulation

Ozone efficiently breaks down organic matter in wastewater, helping to disperse grease cakes and reduce sludge buildup. This improves pumping efficiency and decreases the need for frequent cleanings.

Improvement of water quality

Deep ozone bubbling ensures uniform diffusion in wastewater, promoting oxidation of organic compounds, pathogens, and contaminants. The result is a significant improvement in the quality of the pumped water and a cleaner, safer environment for subsequent processes.

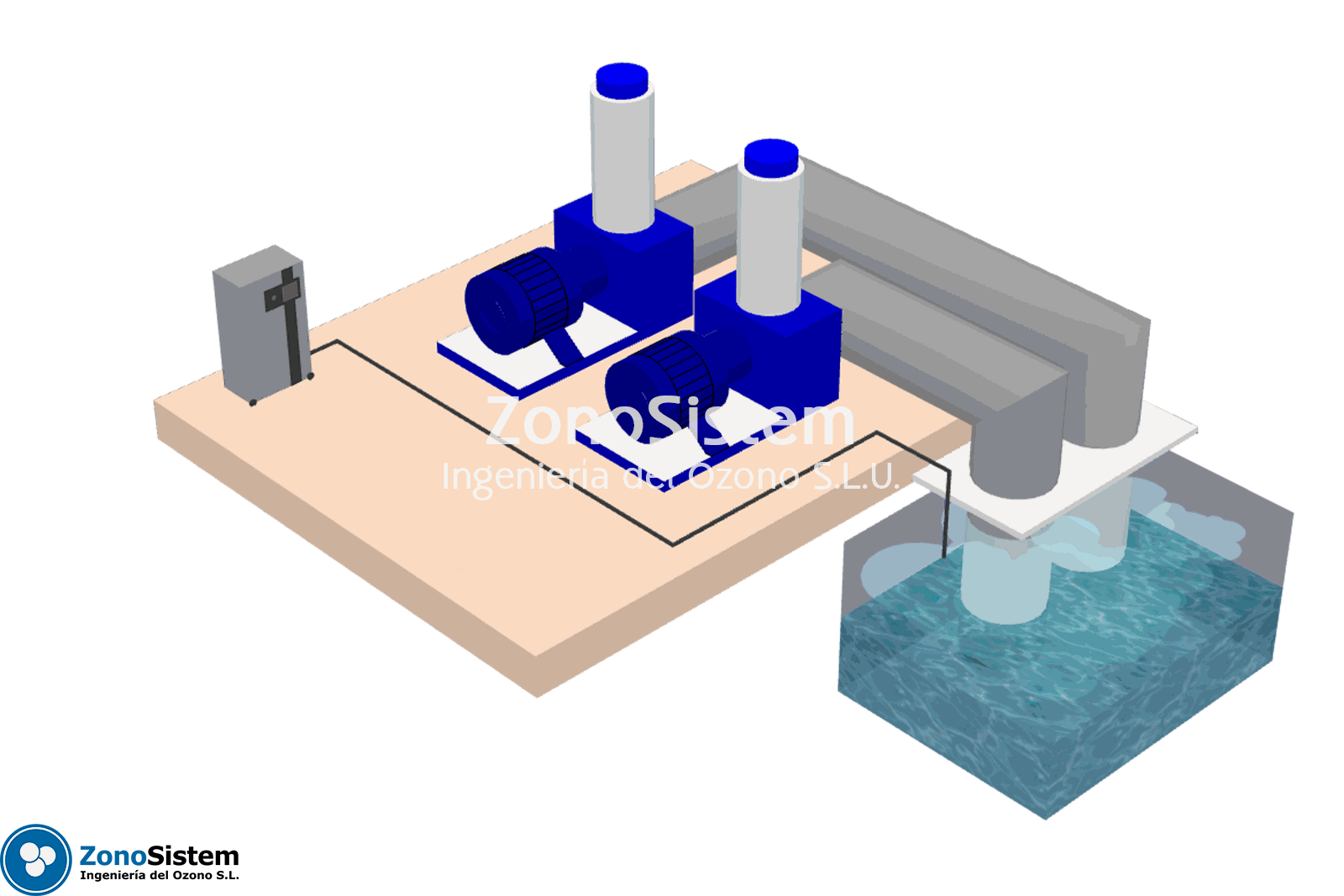

Without labor, automatic

The system generates ozone and injects it into the tank automatically, without the need to apply manual labor in the process. The equipment only needs to be connected to the tank to be treated and provide it with a point of light.

No chemical storage

Ozone cannot be transported or stored, it is generated on site, and it is applied instantly, so it is not necessary to store and manage chemical products, it avoids transport and reduces the carbon footprint.

Agent recognized by the ECHA

Ozone is recognized by the European Chemical Agency and ZonoSistem has all the necessary legalization documentation to be able to apply ozone in its process.

Ozone Injection Techniques in WWPS

Direct injection into the air chamber of the pumping well

This technique allows for the injection of ozone gas into the gas chamber above the water surface. This environment has a high hydrogen sulfide load, and ozone reacts to oxidize it.

Direct injection into the exhaust stack

This method is suitable for WWPS equipped with a channeled injection system. It consists of injecting ozone into the outlet pipe of the extraction stack to reduce odors before discharge into the environment.

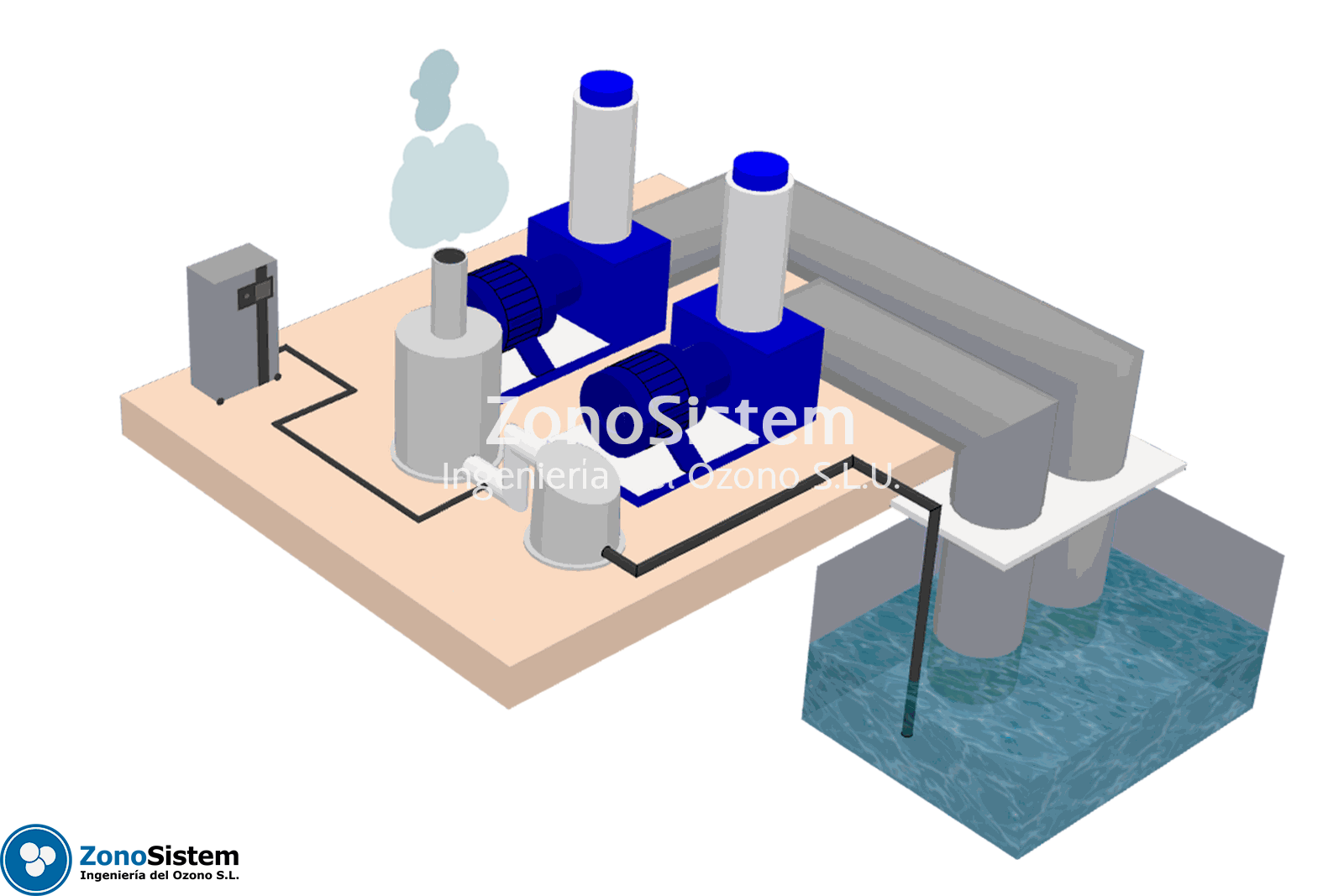

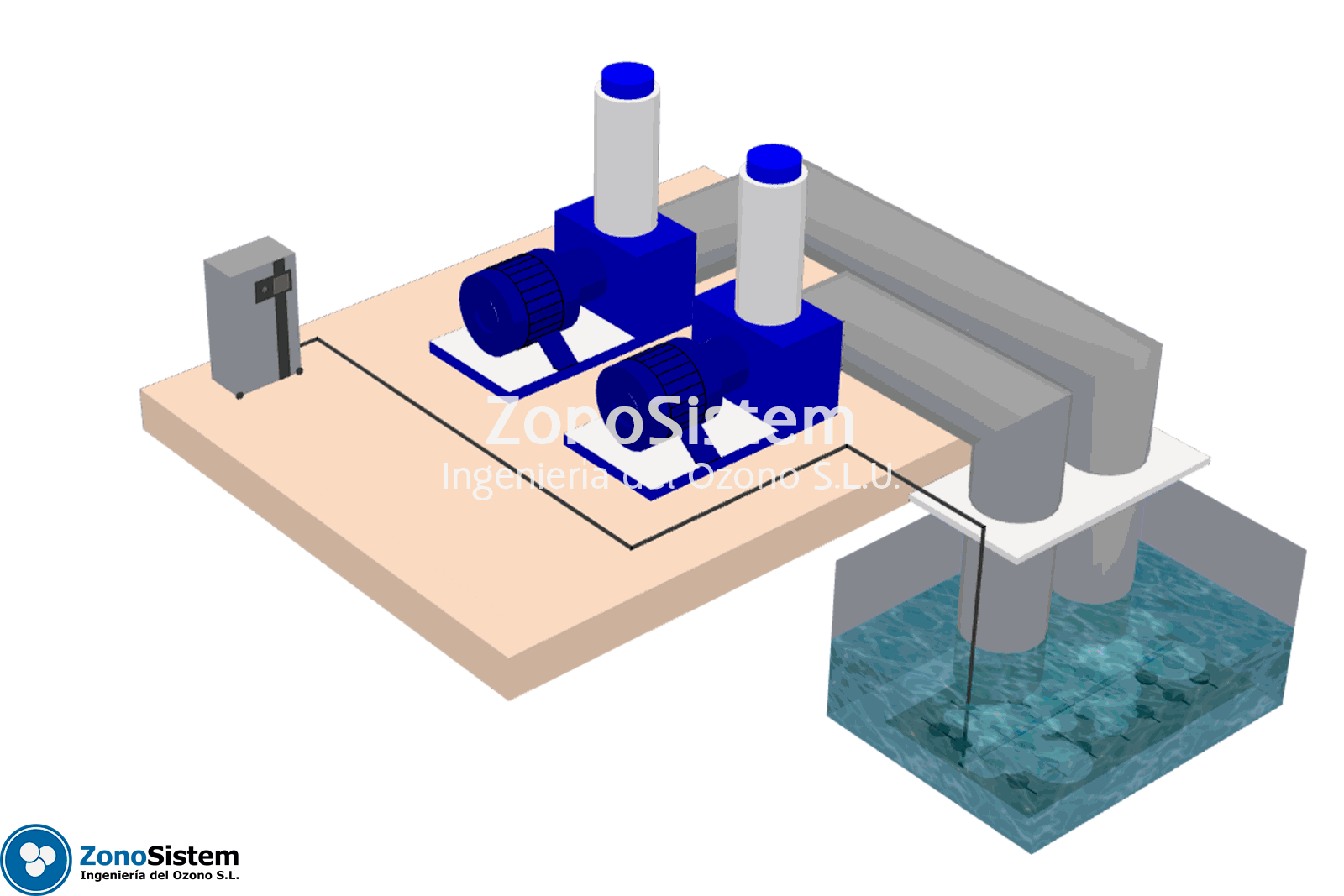

Deep ozonation by bubbling

This is the most efficient technique, as it improves water quality, reduces surface grease layers, and lowers precursors that generate hydrogen sulfide.

Examples of Ozone Use in WWPS

Deep ozonation of pumping pits. Canary Islands

Direct ozonation of extraction towers. Canary Islands

Deep ozonation of pumping pits with direct outfall. Canary Islands

Deep ozonation of seaside promenade pumping pits. Balearic Islands