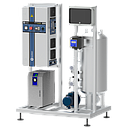

HIDRO VT GZO12-ES Professional Ozone Plant

Ozone Generator Plant type Hidro VT for in-line pressurised water treatment. With Professional Ozone Generator, with compressor, oxygen concentrator, Logo! control, venturi dilution system, pump and contact tower. Ozone production of 12 gO3/h, at 45 g/Nm3 concentration. 230V, 50HZ, 1,45KW.

[Spanish design and manufacture] Ideal for injecting and maintaining high doses of ozone in a pressurized water pipe.

[High performance] Get high doses of dissolved ozone, and a homogeneous mixture, thanks to the pump, venturi and contact tower.

[Auto operation] Controlled by LOGO, with manual power regulation and time programmer.

[Simple Installation] You only have to connect the equipment to the pipe you want to treat and provide it with a light point.

[No replenishment of chemicals] Ozone is generated from the air we breathe.

[Maximum Security] The system controls the entire process and includes an ozone leak sensor.

Manufacturing in 10-15 days

Professional Ozone Generator

Technical specifications

What is it used for?

This equipment is used to dose ozone in a pressurized water pipe, maintaining a constant ozone concentration. It is used to disinfect and purify water and pipes. Widely used in agricultural water treatment, for drip or sprinkler irrigation, in drinking water treatment, waste water, process water, cooling towers, swimming pools, aquariums, etc. Ozone is an excellent disinfectant, which allows you to maintain hygiene both in the water and in the pipes.

Product Details

| Ozone generator | Latest generation GZO12-ES model |

| Oxygen concentrator | With compressor, oxygen concentrator at 95% purity and -30ºC Dew Point |

| Ozone Dilution System | Composed of pump, venturi, 316L stainless steel tank and anti-return safety system |

| Control | By controller Logo!. Daily programmer, alarm and maintenance manager. |

| Communication | Wired Remote ON, Status Relays (Initiated, Generating, Fault). |

| Sensors |

Amps in Ozone, Compressed Air Pressure, Oxygen Pressure and Flow, Door Opening. At the plant: Maximum and minimum pressure switch on the line, manometer. Optional Redox Control and Dissolved Ozone Sensor. |

| Technical Valves | Outlet ozone solenoid valve, oxygen flowmeter with manual regulation. Stainless steel 316L motorized safety anti-return valve on the venturi. |

| Included in the packaging | User manual |

| Ozone Production | 12 gO3/h |

| Ozone concentration |

Maximum = 80g/Nm3 Optimum = 45g/Nm3 |

| Air/Oxygen flow | 5 lpm |

| Power supply | 230V, 50-60Hz |

| Electric Power |

Ozone Generator = 650 W Pump = 750W |

| Hydraulic connection | Inlet and outlet in 2"-H |

| Dimensions | 1100 x 720 x 1500 mm (Width x Depth x Height) |

| Packed size | 1250 x 900 x 1750 mm (Width x Depth x Height) |

| Weight | 230 Kg |

| Humidity | <85% |

| Room temperature | 5-40ºC |

| Hydraulic Working Pressure | Between 0 and 6.5 bar |

| Fluid temperature | 5-30ºC |

| Fluid freatures | Ǿ Solids < 1mm; Suspended solids (SS)<150mg/l; Density = 1 g/cm3 ± 5% |

| Working pressure | 0 - 0,4 bar |

Room fittings

The room must be well ventilated, and provide an extraction system in case of leaks. Install sign with safety warnings. It is recommended that the room have a drainage box.

| Made by | ZonoSistem |

| Made in | Spain |

| Sold from | 2015 |

| Last revision | 2021 |

| Warranty | 2 years extendable indefinitely, with maintenance contract |

| Certificates | CE, BIOCIDA PT2, PT4, PT5, PT11 |

| UFI number | G000-W09P-Y00M-TV8V |

Functioning

This HIDRO VT ozone plant includes a Logo! control from which different operating time slots can be easily and intuitively programmed throughout the day by means of a scheduler. When the unit receives the operating order, the refrigeration circuit is activated, and the compressor starts up, takes the air from the atmosphere, filters it, dries it and introduces it into the PSA, where the nitrogen is removed from the air and the oxygen is concentrated to 95% purity. This oxygen flow reaches the generation core, where the corona discharge is applied and the oxygen is converted into ozone. With the oxygen flow meter, the desired flow rate can be regulated. The ozone is then channelled to the venturi, where the ozone is injected into the customer's line water, homogenised in the tank and given a contact time for the ozone to react, disinfect and purify.

Included documentation

Safety manual.

User manual, installation and commissioning.

Maintenance manual.

Declaration of conformity.

Certificate of guarantee.

Compliance with the biocidal regulation.

Results of the Quality Test in the factory.

Technology

This GZO ozone generator uses high frequency corona discharge technology with ceramic dielectric.